Installation & Operation

What do I Need to do to install this system on my yard?

- 3TEK includes in your purchase price the reassembly on your yard of the system purchased.

- Factory Certified crew will reassemble

- The Bravo shredder in typically 2-3 days

- The Mobile DS in 1-2 days

- Total System = 5 days

- Factory Training Included: Once the complete system is reassembled 3TEK Factory instructors will conduct operation and maintenance training to your operating staff.

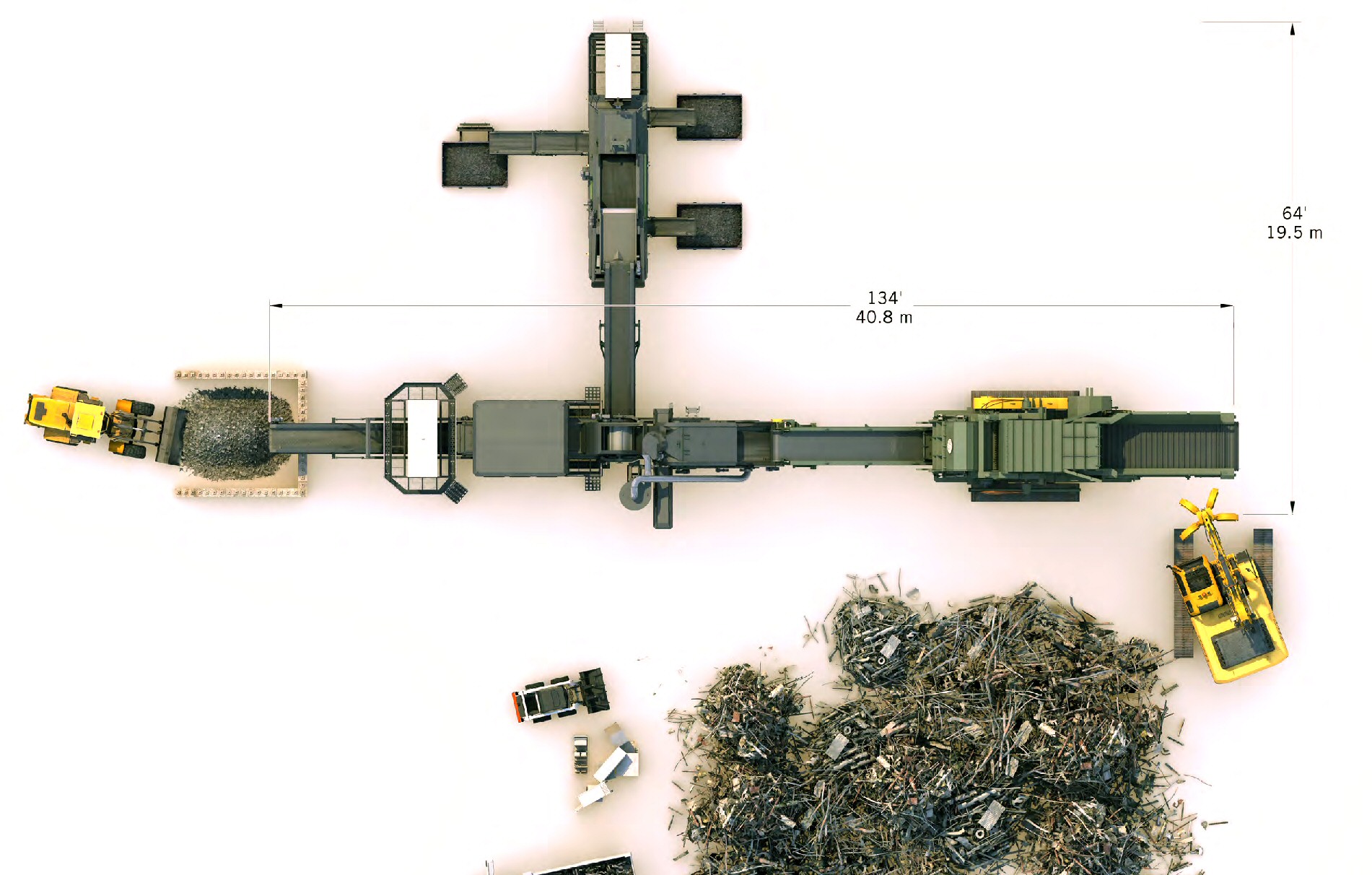

How much space does it take?

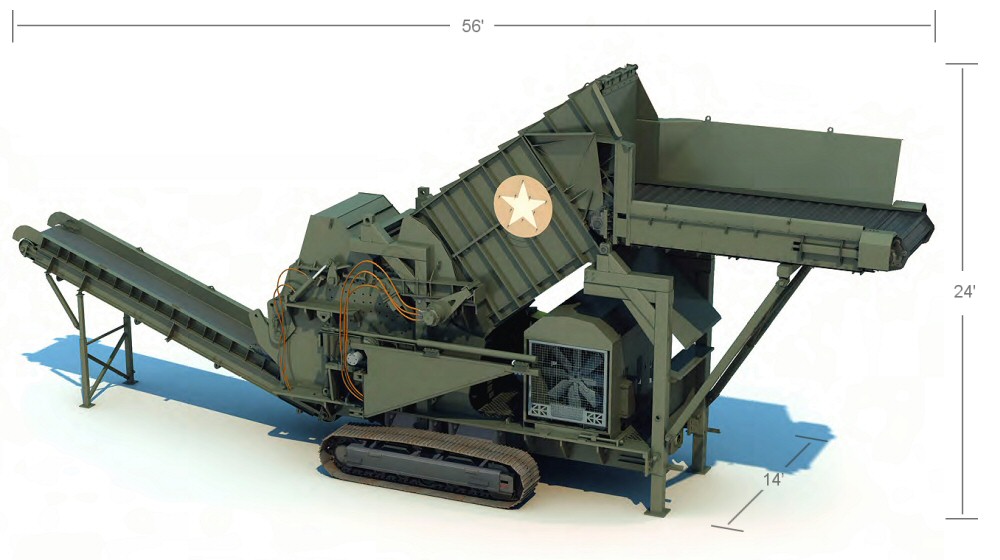

Bravo Shredder

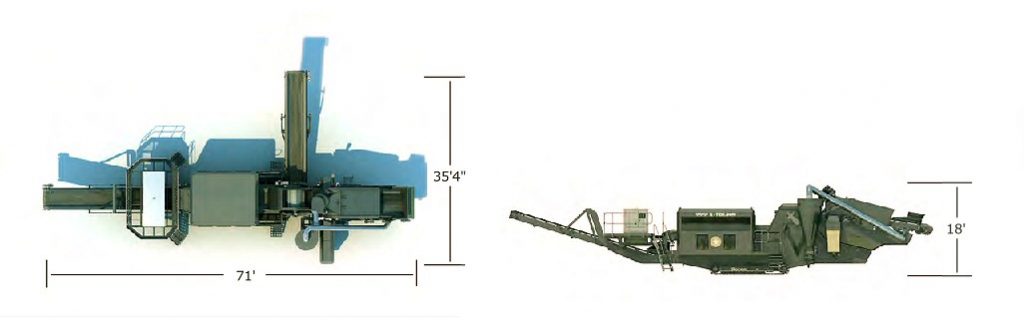

RECON

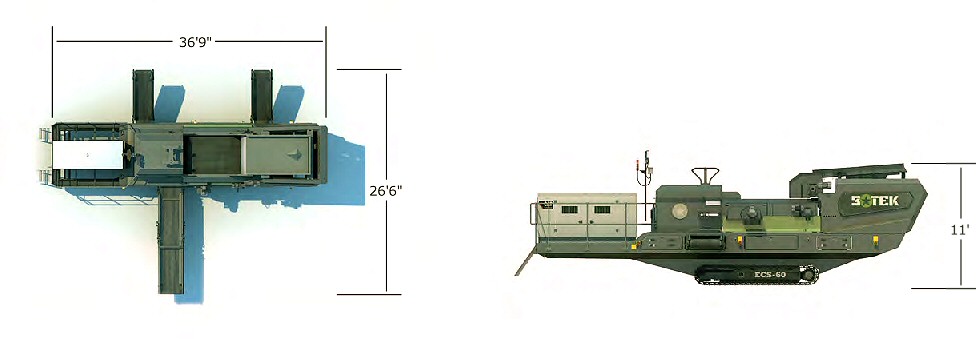

ECS 60

FAQ

- Track Mounted = Low Ground Pressure

- All three machines are track mounted and spread their heavy weight over this track area

- Bravo weighs 322,000 lbs. but has a 26 PSI because of the CAT 345 track undercarriage

- Best Option: YES, add concrete

- Under the Shredder and Mobile DS

- Enables easier clean up

- Better Option: Add some concrete

- Under the Bravo Shredder only

- Good Option:

- Any compacted level gravel surface can work.

- Alternative: Get shredding and pour concrete later.

- Tough question but most likely yes. All states and municipalities are different.

- Regulations and interpretations of the regulations keep changing.

- We recommend contacting your local environmental consultant here and seek their services.

- This is a matter of interpretation and depends largely on the composition of the in-flowing scrap

- A Water injection system is provided as standard equipment whose purpose is to knock down dust and smoke

- Most customers are surprised as to how quiet the machine is/are.

- Most customers say the material handlers loading the Bravo system is louder than the shredding system.

- Certainly, noise is contingent on the inflowing scrap mixture:

- For example: cast ferrous is very loud by itself.

- If you mix the scrap with mixed metals this quiets it down

- The noise is not symmetrical and varies depending where you are in the perimeter.

- Sound study: We have a certified sound study that we can share.

- NONE for the shredding system!

- Water is needed for the dust suppression water injection system

- Material Handler to load the shredder

- Recommended with an orange peel grapple that turns

- Loading height: 20’ so long enough boom

- Elevated cab is a bonus

- Wheel Loader:

- For taking processed metal away from the system

- Skid Steer loader: Clean up and secondary material mover

- Do I need a dedicated shredder operator?

- NO. The Material Handler Operator can load AND operate the shredder controls. It’s that easy!

- Depends on the number of machine = the system selected

- Bravo Shredder Only: two

- Material Handling operator loading the shredder: one

- Individual relocating finished metal products: One

- Bravo Shredder with Recon: Four to six

- Material Handling operator loading the shredder: one

- Two to four pickers in the Picking Station

- One individual relocating finished metal products

- Bravo Shredder + Recon + Eddy Current Separator (ECS 60) 4-6

- Material Handling operator loading the shredder: one

- Two to four pickers in the Picking Station

- One individual relocating finished metal products

- Bravo Shredder Only: two

- Ferrous density:

- 65-70 Lbs./cubic foot capable

- Capable??? What does this mean?

- Capable = the shredder is only as good as the material it is being fed. If you feed it a balanced blend of product it will produce very acceptable density for most foundries.

- Ferrous Cleanliness?

- Very clean ferrous results when using our Mobile DS and operating it properly.